Our Process

Producing true carbon fiber parts takes a lot more time and care than traditional injection replicas. The human touch is required in nearly every step of production to create a truly superior product. Below is a general overview of the process from design to finished product.

3D Scanning

Using 3D scanners, we capture OEM part data on and off vehicle. That scan data is then reverse engineered into CAD and adjsutments/improvements made for production in carbon fiber.

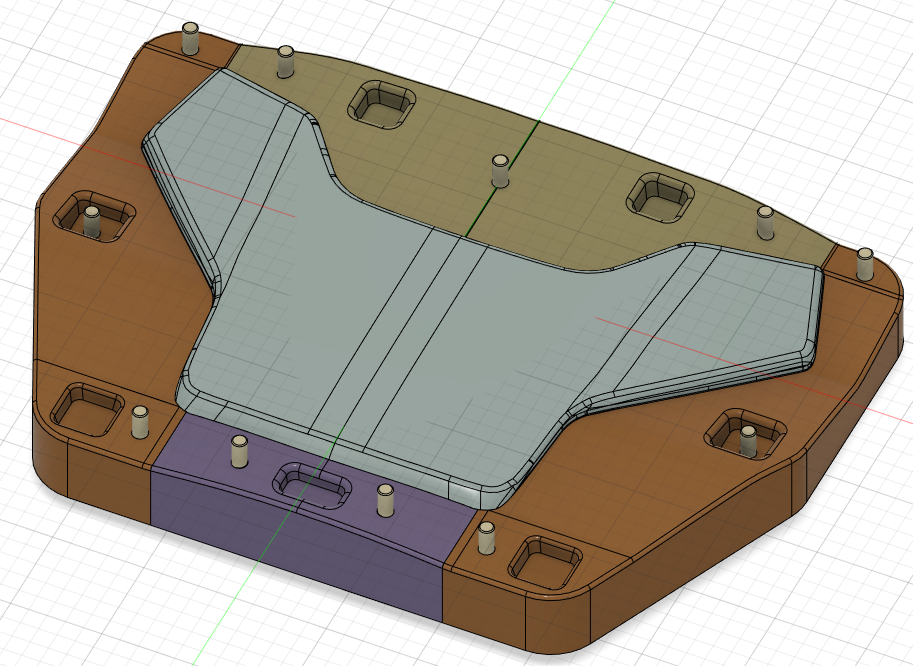

Mold Design & Production

Production molds designed around part data and CNC milled out of steel.

Autoclave Forming

Mold with carbon fiber material inlaid is placed in autoclave where it is heated and vacuum formed into shape.

Edge Trimming

Any excess material is trimmed from the part manually and inspected for any flaws.

Sandblasting

Initial sandblasting of surface is done to ensure smooth surface for clearcoat.

Fine Polishing

Any areas that need additional polishing are addressed manually to ensure no missed areas on hard-to-reach areas.

Clearcoat Painting

Visible surfaces are sprayed with clearcoat to acheive a glossy finish and protect the surace of the part.

Final Buff/Polish

Surfaces are then polished after clearcoating to ensure glossy finish and inspect for any defects. Product is then safely packed in foam sleeves for shipment.